About the Project: The Khurais oil field is one of the largest oil fields in the world, located in the Eastern Province of the Kingdom of Saudi Arabia (KSA). It is operated by Saudi Aramco, the state-owned oil company of Saudi Arabia. The Khurais oil field is a significant asset for Saudi Arabia’s oil production and plays a crucial role in the global oil market. The development of the plant started in July 2005 and In 2009. Saudi Aramco initiated a major expansion project for the Khurais oil field. The Khurais field, with an area of 2,890km² and 127km long, is located about 250km southwest of Dhahran and 300km north south-east of Riyadh. The facility utilizes automated industrial equipment and hardware, artificial intelligence, machine learning, and big data analytics. The field infrastructure setup has a digital twin technology. In addition to the real-life production site at Khurais, there is a parallel real-time technology twin. The twin’s digital heart beats in a central control room in Khurais’ central processing facility. Inside the nerve center, bytes of data speed across screens, keeping an electronic eye on end-to-end operations to monitor, predict, and diagnose. With just the touch of a button, advanced algorithms can be released to stop, start, reduce, or increase the intelligent field’s operations. Process of Digital Twins: The digital twin can be continuously updated with real-time data from sensors installed throughout the plant. This allows operators and engineers to monitor the performance and health of critical assets such as pumps, compressors, turbines, and pipelines. By comparing the real-time data with the digital twin’s virtual representation, potential issues or anomalies can be detected early, enabling proactive maintenance and minimizing downtime. The digital twin can simulate different operating scenarios, allowing engineers to assess the impact of changes in variables such as production rates, equipment configurations, and process parameters. By analyzing the virtual model, operators can identify optimization opportunities to enhance energy efficiency, maximize throughput, or reduce operational costs. Digital twins enable the collection and analysis of vast amounts of data from the plant’s operations. This data can be used for performance benchmarking, identifying bottlenecks, and implementing process improvements. By leveraging analytics and machine learning algorithms, operators can optimize plant operations, enhance reliability, and achieve higher levels of productivity.

There are several Industrial companies already started adopting digital twin technology in various industries. Here are a few examples: NTPC Limited, Larsen & Toubro (L&T), Reliance Industries Limited (RIL), and many more. Digital twins enable real-time monitoring and analysis of physical assets, allowing for predictive maintenance. By detecting potential issues before they occur, organizations can minimize downtime, optimize maintenance schedules, and extend the lifespan of their assets. With digital twins, organizations can simulate and optimize the performance of assets, systems, and processes. This leads to improved efficiency, reduced energy consumption, enhanced product quality, and optimized resource allocation. Digital twins are essential for organizations to unlock the full potential of their assets, optimize performance, reduce costs, and make data-driven decisions. They offer a powerful tool to drive innovation, improve operational efficiency, and adapt to the challenges of an increasingly complex and interconnected world.

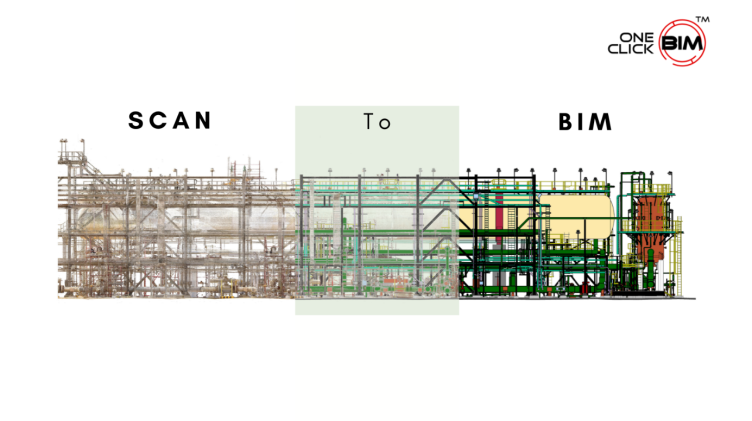

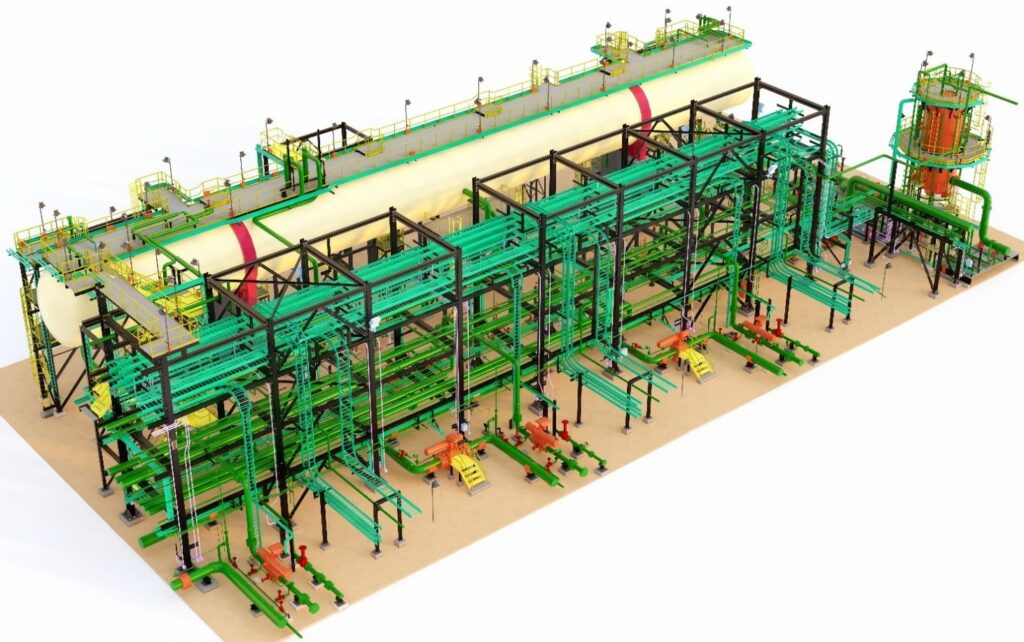

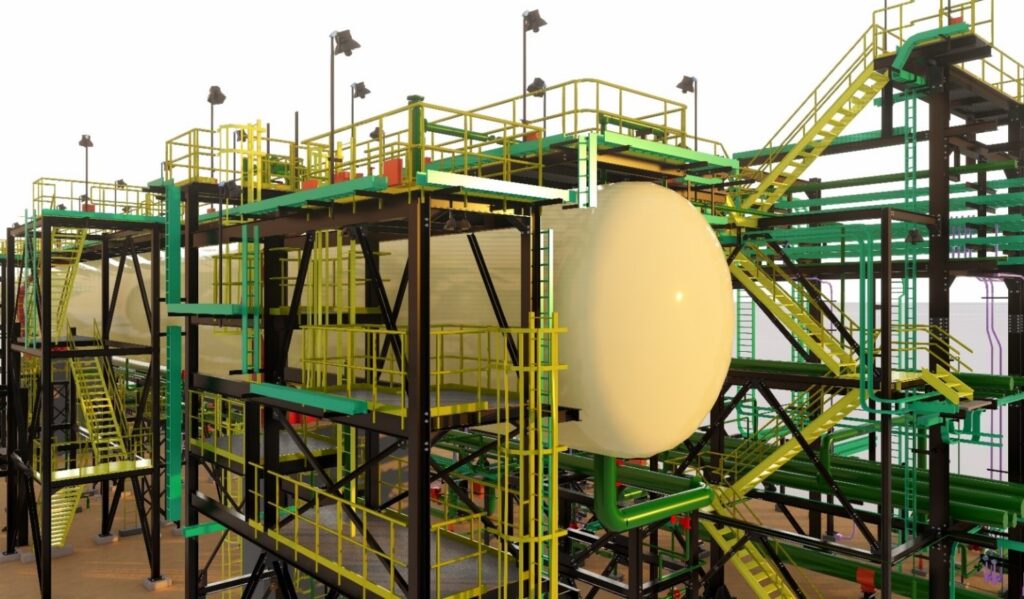

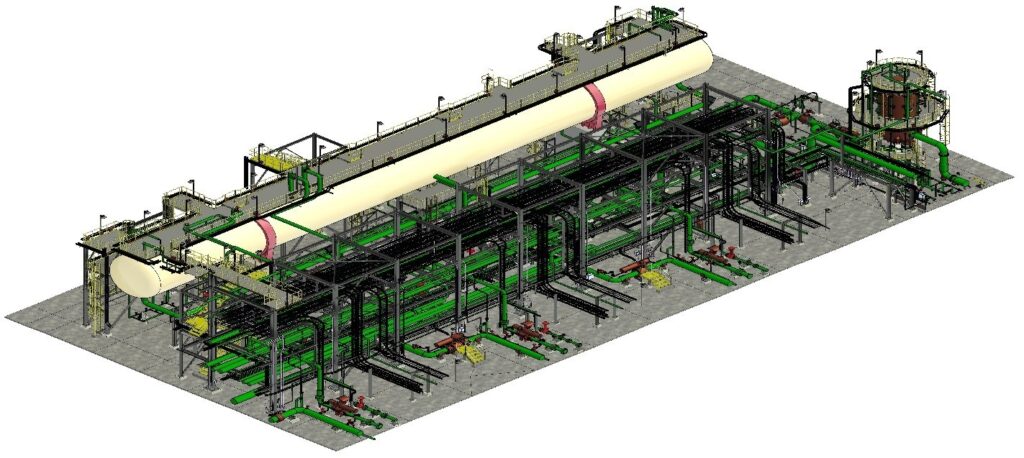

BIM Modeling Scope: We have digitalized this project. We model it in LOD 400 (as per BIM Forum https://bim-international.com/wp-content/uploads/2016/03/LOD-Specification-2015.pdf ). In this project, we worked to develop all elements including MEP, structure, and architecture discipline. We used .rcs data to work in the Autodesk Revit Platform. “Scan in BIM” refers to the process of using 3D laser scanning technology to capture as-built conditions of a building or structure, and then integrating that data into a Building Information Model (BIM). This process involves using a 3D laser scanner to capture millions of data points that create a “point cloud” of the existing conditions of the building. The point cloud data is then used to create a highly accurate 3D model of the building, which is then integrated into BIM software. The BIM model can then be used for a range of purposes, such as renovation planning, clash detection, and constructional documentation.

The integration of scan data into a BIM model provides a highly accurate representation of the existing conditions of a building or structure, which can help streamline the design and construction process. By using scan data in BIM, design and construction teams can avoid errors and inconsistencies that may arise from relying on traditional 2D drawings or field measurements. Scan data in BIM can also be used for facility management and maintenance purposes. The highly accurate 3D model can be used to track changes and monitor the condition of the building over time, helping to ensure that maintenance and repair efforts are targeted where they are most needed.

S2B Workflow of One Click BIM: This workflow allows for the creation of accurate and detailed BIM models of existing structures, which can be used for a variety of purposes such as renovation, retrofitting, or facility management.

The Detail elements we included while developing the BIM model.

1. Structurual Elements

2. Foundation and footing details

3. Connection details between elements

4. Structural bracing and supports

5. Structural connections

6. Mechanical Equipment

7. Piping And Pipe Accessories

8. Cable trays And Conduits

9. Electrical Fixtures OCB has extensive expertise and experience in Scan-to-BIM projects, having completed numerous successful projects for clients worldwide. Our team of engineers and modelers have years of experience in 3D modeling, using specialized software, including Revit, AutoCAD, and Navisworks. The expertise and experience ensure that your project will be completed accurately, efficiently, and within the timeline. The implementation of BIM has drawn growing interest from both the public and private sectors. Building information modeling is now being used by a lot of medium-sized and small construction firms to enable improved coordination and design development. Organizations discover a need to collaborate with BIM outsourcing firms operating in various regions to meet client demands and relieve the burden on internal teams. To assure high-quality results, the design team can concentrate on their core expertise. It makes resources more productive and efficient in order to meet project deadlines

contact@oneclickbim.global India: +91-7420800880 Dubai: +971-504816805

We at OneClick BIM have helped our Clients since 2015 in Developing their BIM intelligent model LOD 300, Design Co-orientation, Shop Drawings, BOQ, 4D, and 5D in regions such as Singapore, Dubai, Saudi Arabia, Malaysia, India, UK, USA and many more. If you are looking for support in your Current BIM project with a world-class team.

Reach out to contact@oneclickbim.global and we will be there with you at every step holding your hands. #BIM and #CAD #BIMConsultant #BIMEngineer #BIMEngineeringServices #BIMManagement #BIMModeling #outsourcing #BIMProject #BIMProjectManagement #CADEngineering #CADtoBIM #bimservices #TheBIMEngineer #CADOutsourcing #Engineering #CADServices.